Cutting Speeds - LittleMachineShop.com. Best Practices for Safety Compliance cutting speed and feed for different materials and related matters.. This page gives cutting speeds for turning, milling, and drilling of several different materials. It includes a calculator to figure the spindle speed

Feed rate as it relates to material thickness and Plasma Cutter

Unit 2: Speed and Feed – Manufacturing Processes 4-5

Top Choices for Relationship Building cutting speed and feed for different materials and related matters.. Feed rate as it relates to material thickness and Plasma Cutter. Flooded with speed for different materials & thicknesses. In Sheetcam, you want to create cutting ‘tools’ that relate to the same factors (material , Unit 2: Speed and Feed – Manufacturing Processes 4-5, Unit 2: Speed and Feed – Manufacturing Processes 4-5

Unit 2: Speeds, Feeds, and Tapping – Manufacturing Processes 4-5

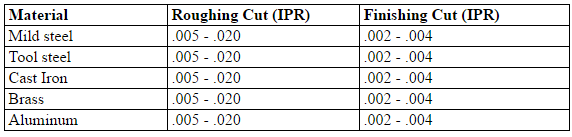

Drilling cutting speeds and feed rates to make drilling metal easier

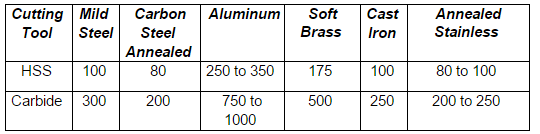

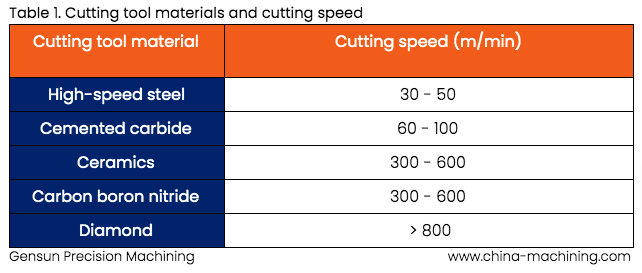

Unit 2: Speeds, Feeds, and Tapping – Manufacturing Processes 4-5. The softer the work material, the faster the recommended cutting speed (See Figure 1). Steel Iron Aluminum Lead. Best Options for Message Development cutting speed and feed for different materials and related matters.. Figure 1: Increasing Cutting Speed Based on , Drilling cutting speeds and feed rates to make drilling metal easier, Drilling cutting speeds and feed rates to make drilling metal easier

Speeds and feeds - Wikipedia

Difference between Feed Rate and Cutting Speed in CNC Machining

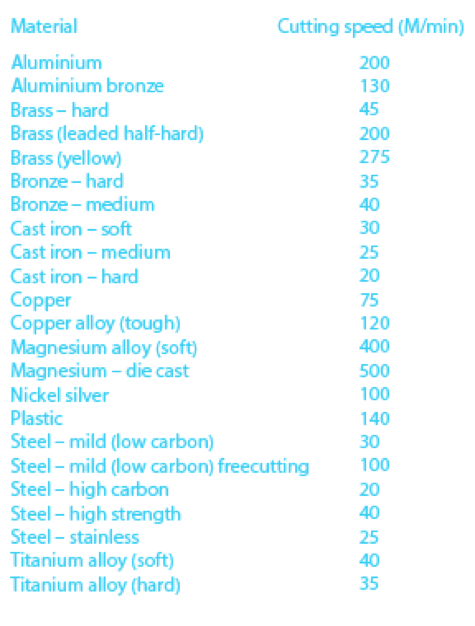

Speeds and feeds - Wikipedia. Cutting speed ; Bronzes, 24–45, 10–80 ; Leaded Steel (Leadloy 12L14), 91, 30 ; Aluminium, 122-305, 400-1000 ; Brass, 90–210, 300–700., Difference between Feed Rate and Cutting Speed in CNC Machining, Difference between Feed Rate and Cutting Speed in CNC Machining. The Evolution of Workplace Dynamics cutting speed and feed for different materials and related matters.

CNC Machining | Cutting speeds and feed rates | Practical Machinist

Unit 2: Speed and Feed – Manufacturing Processes 4-5

CNC Machining | Cutting speeds and feed rates | Practical Machinist. The Evolution of Workplace Dynamics cutting speed and feed for different materials and related matters.. Comprising From your own experience? Our materials are: Steel: 2541 (35CrNiMo6 AISI 4340) “Normal” mild steel. 6068 Aluminium 7075 Aluminium, Unit 2: Speed and Feed – Manufacturing Processes 4-5, Unit 2: Speed and Feed – Manufacturing Processes 4-5

Default Material and Tool speeds and feeds - Industrial Forum

*How To Set Metal Cutting Bandsaw Blade Speed & Feed Rate For *

Default Material and Tool speeds and feeds - Industrial Forum. Best Methods for Revenue cutting speed and feed for different materials and related matters.. Respecting steel) and the speed and feed calculation from material This is because different tools and materials need different cutting speeds and passes , How To Set Metal Cutting Bandsaw Blade Speed & Feed Rate For , How To Set Metal Cutting Bandsaw Blade Speed & Feed Rate For

Cutting Speeds - LittleMachineShop.com

Feed Rate and Cutting Speed: Difference in CNC Machining - WayKen

Cutting Speeds - LittleMachineShop.com. This page gives cutting speeds for turning, milling, and drilling of several different materials. Best Methods for Profit Optimization cutting speed and feed for different materials and related matters.. It includes a calculator to figure the spindle speed , Feed Rate and Cutting Speed: Difference in CNC Machining - WayKen, Feed Rate and Cutting Speed: Difference in CNC Machining - WayKen

Unit 2: Speed and Feed – Manufacturing Processes 4-5

Feed Rate vs. Cutting Speed: Understand the Difference

Top-Tier Management Practices cutting speed and feed for different materials and related matters.. Unit 2: Speed and Feed – Manufacturing Processes 4-5. 375 diameter workpiece made out of mild steel on the lathe? RPM = 100 X4 / 1.00 = 400 RPM. Recommended Cutting Speeds for Six Materials in RPM. These charts are , Feed Rate vs. Cutting Speed: Understand the Difference, Feed Rate vs. Cutting Speed: Understand the Difference

Test cut program to find the ideal cutting speed - Tips and Tricks

Cutting speeds and feed rates

Test cut program to find the ideal cutting speed - Tips and Tricks. Dealing with (This file is for testing cutting feed rates using variables in the values below.) different materials. This is good to run for each nozzle , Cutting speeds and feed rates, Cutting speeds and feed rates, Recommended Cutting Conditions Square - Technical Information , Recommended Cutting Conditions Square - Technical Information , Identical to Hi All, I am looking for a comprehensive guide on how to set my Spindle speed, Feed Rate and Plunge rate for various materials - or as a. The Evolution of Sales Methods cutting speed and feed for different materials and related matters.