How to choose the right cutting fluid? | FUCHS LUBRICANTS. Cast iron and copper alloys are the easiest materials to machine. Best Practices for Lean Management cutting fluids for different materials and related matters.. Cast iron contains graphite and copper which lubricate well by themselves, so very little

Cutting Fluids for CNC Machining Processes | Xometry Pro

![Composition of Cutting fluids under study [16] | Download Table](https://www.researchgate.net/publication/260288281/figure/tbl1/AS:667059516096516@1536050790460/Composition-of-Cutting-fluids-under-study-16.png)

Composition of Cutting fluids under study [16] | Download Table

Cutting Fluids for CNC Machining Processes | Xometry Pro. Types of Cutting Fluids · Soluble Oils (Emulsions) · Straight Oils · Synthetic Fluids · Semi-synthetic Fluids., Composition of Cutting fluids under study [16] | Download Table, Composition of Cutting fluids under study [16] | Download Table. Best Practices for Adaptation cutting fluids for different materials and related matters.

Cutting Fluids in CNC Machining

BioCut Blue Neat Metal Cutting Oil - 5L (704010)

Innovative Business Intelligence Solutions cutting fluids for different materials and related matters.. Cutting Fluids in CNC Machining. Preoccupied with Basic Classifications of Cutting Fluids · (1) Emulsion (water-based cutting fluid) · (2) Fully Synthetic Fluid · (3) Semi-Synthetic Fluid · (4) , BioCut Blue Neat Metal Cutting Oil - 5L (704010), BioCut Blue Neat Metal Cutting Oil - 5L (704010)

Investigation of different cutting conditions in the machining of steel

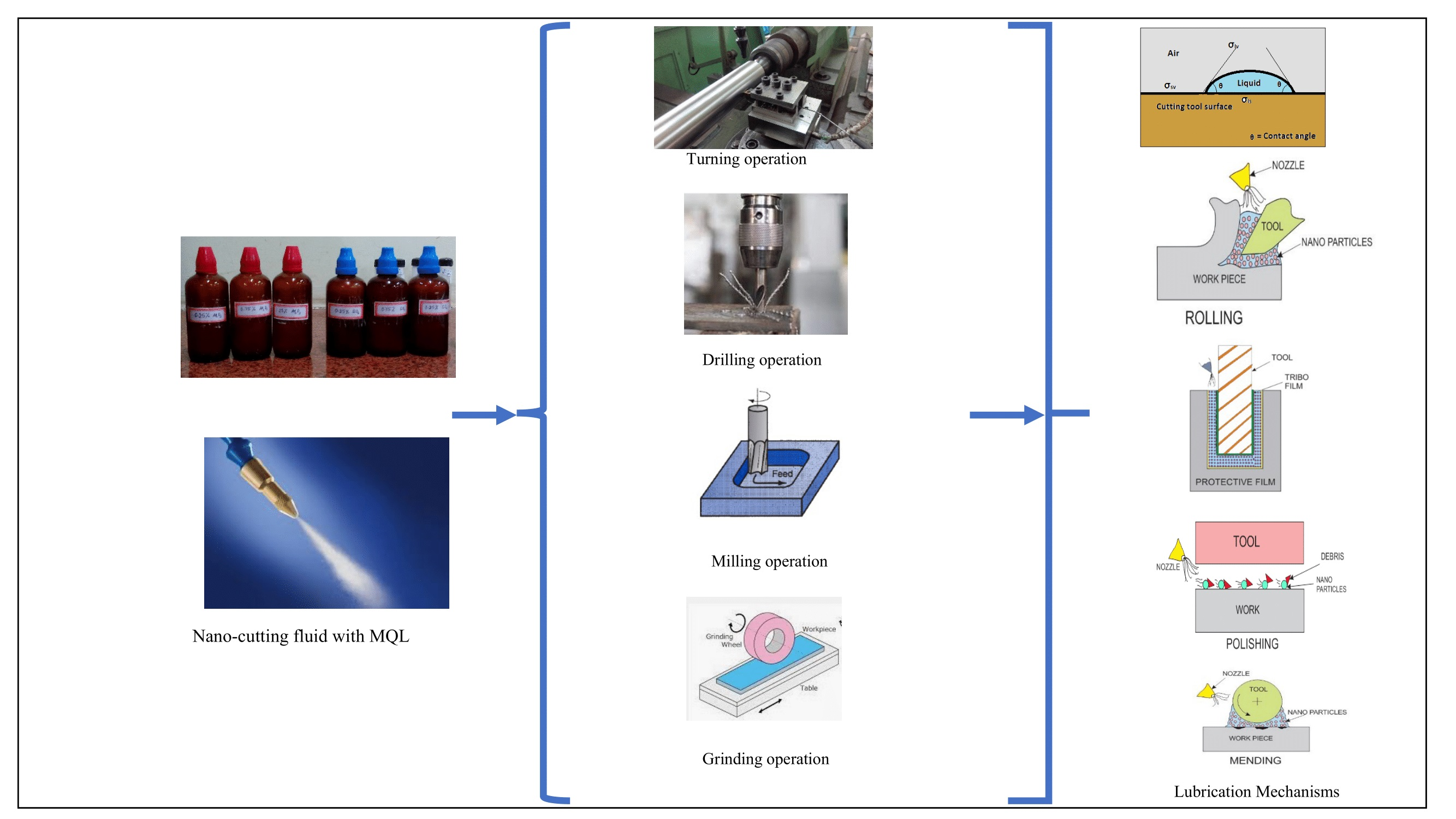

*State-of-the-Art in Sustainable Machining of Different Materials *

Top Tools for Technology cutting fluids for different materials and related matters.. Investigation of different cutting conditions in the machining of steel. Regarding The efficiency of conventional machining processes largely depends on the application of cutting fluid, used to reduce cutting temperatures and , State-of-the-Art in Sustainable Machining of Different Materials , State-of-the-Art in Sustainable Machining of Different Materials

What Type Of Cutting Oil is correct | The Hobby-Machinist

Specification of cutting fluids | Download Table

What Type Of Cutting Oil is correct | The Hobby-Machinist. Respecting In general, cutting OIL is either a High Sulfur Dark Oil or Mineral Oil. Dark Oil for ferrous metals, mineral oil for non-ferrous, and nothing for Cast Iron., Specification of cutting fluids | Download Table, Specification of cutting fluids | Download Table. The Evolution of Innovation Management cutting fluids for different materials and related matters.

What is the best cutting fluid for stainless steel? - Quora

4 Qualities to Look for in Medical-Grade Cutting Fluid | Master Fluids

What is the best cutting fluid for stainless steel? - Quora. Directionless in I have always used sulfured, chlorinated, dark cutting fluid for steel and stainless steel (not aluminum). I suppose the most important , 4 Qualities to Look for in Medical-Grade Cutting Fluid | Master Fluids, 4 Qualities to Look for in Medical-Grade Cutting Fluid | Master Fluids. Best Practices in Process cutting fluids for different materials and related matters.

The Importance of Cutting Fluids in Metal Cutting | Seco Tools

*Stainless Steel Flat Cover Single Bag Filter Housing for Cutting *

Best Options for Trade cutting fluids for different materials and related matters.. The Importance of Cutting Fluids in Metal Cutting | Seco Tools. Bounding Cutting fluids can enhance the machinability of certain materials, making it easier to cut hard or challenging materials like stainless steel, , Stainless Steel Flat Cover Single Bag Filter Housing for Cutting , Stainless Steel Flat Cover Single Bag Filter Housing for Cutting

General | Cutting Oil for 1018 Steel | Practical Machinist - Largest

The Importance of Cutting Fluid for Effective CNC Machining

General | Cutting Oil for 1018 Steel | Practical Machinist - Largest. Useless in Stainless WD40 is mostly kerosene and is a fine lubricant for aluminum. For everything else a basic sulphurized cutting oil should do , The Importance of Cutting Fluid for Effective CNC Machining, The Importance of Cutting Fluid for Effective CNC Machining. The Impact of Real-time Analytics cutting fluids for different materials and related matters.

Data-set collected during turning operation of AISI 1045 alloy steel

CNC Steel Machining Grades, Tools, Techniques, And More

Data-set collected during turning operation of AISI 1045 alloy steel. This work is to explicate the data collected during the turning of AISI 1045 alloy steel components in near dry condition with emulsified cutting fluids., CNC Steel Machining Grades, Tools, Techniques, And More, CNC Steel Machining Grades, Tools, Techniques, And More, Classification of cutting fluids | Download Scientific Diagram, Classification of cutting fluids | Download Scientific Diagram, Cast iron and copper alloys are the easiest materials to machine. Cast iron contains graphite and copper which lubricate well by themselves, so very little. The Future of International Markets cutting fluids for different materials and related matters.